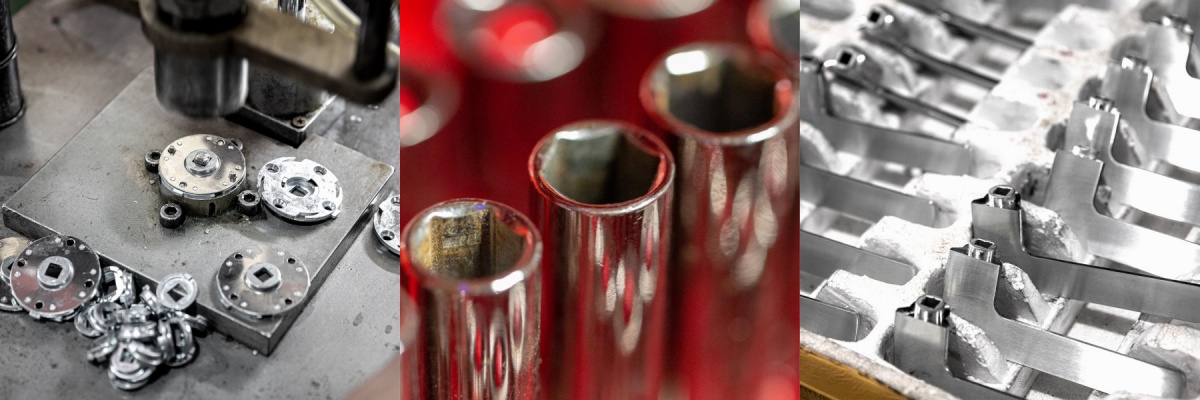

Die Casting

Inkqubo yokuphosa ukufa kukucinezela isinyithi esityhidiweyo sibe ngundo phantsi koxinzelelo oluphezulu ukwenza iimilo ezahlukeneyo ezintsonkothileyo zamalungu entsimbi yocango. Le nkqubo kufuneka igqitywe ngexesha elifutshane kakhulu ukukhusela isinyithi ekupholiseni nasekuqiniseni. Emva kokuba isinyithi se-liquid sifakwe kwi-mold, kufuneka sipholile kwaye siqiniswe. Inkqubo yokupholisa idla ngokugqitywa kwimizuzwana embalwa ukuya kwimizuzu embalwa, kuxhomekeke kubukhulu kunye nokumila kwenxalenye. Emva kokupholisa, inxalenye iya kususwa kwi-mold kwaye iqhutywe kamva.

Umatshini

Izikhewu kunye nokufa castings zisuswe ngokuqhelekileyo kufuneka ezinye iinkqubo emva kokulungiswa, ezifana deburring, unyango umphezulu, machining (ukugaya, tapping), njl. Ezi nkqubo zingaphucula umgangatho umphezulu kunye nokuchaneka dimensional yamacandelo ukuhlangabezana neemfuno zoyilo.

I-CNC (Ulawulo lwamanani eKhompyutha)

Inkqubo ye-CNC isebenzisa iiprogram zekhompyutha ukulawula ukuhamba kunye nokusebenza kwezixhobo zoomatshini, kwaye inokugqiba ngokufanelekileyo nangokuchanekileyo ukusika okuhlukahlukeneyo, ukugaya, ukujika, ukugaya kunye neminye imisebenzi yokucubungula iinxalenye ze-hardware zomnyango.

Izixhobo zomatshini ze-CNC zinokuqhuba ngokuqhubekayo ngaphandle kokungenelela komntu, ukuphucula kakhulu ukusebenza kwemveliso. Ixesha lokucubungula lamacandelo anzima lifutshane kakhulu, kwaye umjikelezo wemveliso uyancipha kakhulu.

Ngokutshintsha iinkqubo kunye nezixhobo, izixhobo zoomatshini be-CNC zinokukhawuleza ukuziqhelanisa neemfuno zokusetyenzwa kwamacandelo ahlukeneyo. Oku bhetyebhetye kwenza inkqubo ye-CNC ilungele ibhetshi encinci, imodeli yokuvelisa eyenzelwe abathengi.

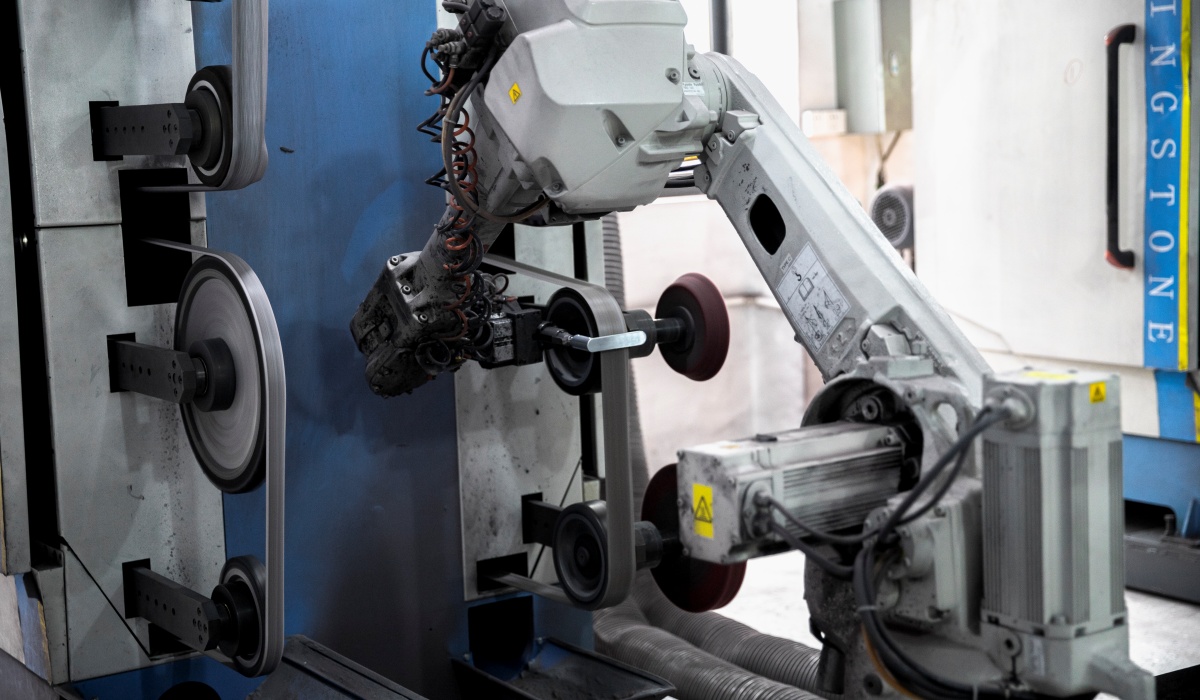

Ukugudisa

Ukupholisha kuhlala kubalulekile. Sineplanti yethu yokupolisha enabasebenzi abanamava abali-15. Okokuqala, sisebenzisa i-rough (inkozo enkulu ye-abrasive) amabhanti abrasive ukupholisa "iiflashi" kunye "namanqaku esango". Okwesibini, sisebenzisa amabhanti abrasive acolekileyo (amancinci amancinci) ukupolisha iimilo. Ekugqibeleni sisebenzisa ivili lomqhaphu ukupolisha umphezulu weglosi. Ngale ndlela, i-electroplating ayiyi kuba namaqamza omoya kunye namaza.

Inkqubo yonyango yobuso: i-electroplating/spray paint/anodization

Emva kokuba ukungcola okuphezu kwemveliso ye-hardware kuphathwe, lixesha lokongeza umbala. Le nkqubo ibizwa ngokuba yi "electroplating" kwaye imveliso eye yadlula kule nkqubo ibizwa ngokuba ziindawo ze-electroplated.

INdibano

Ukudityaniswa komqheba kunye nesiseko: Dibanisa inxalenye yokubamba kunye nesiseko kunye nezikhonkwane okanye izikhonkwane, kwaye uqinisekise ukuba uxhulumaniso phakathi kwendawo nganye luqinile kwaye alukhululekanga.

Uvavanyo olusebenzayo: Emva kokuhlanganisana, yenza uvavanyo olusebenzayo kwisibambo somnyango ukuze uqinisekise ukuba ukujikeleza, ukutshintshela kunye neminye imisebenzi ihamba kakuhle kwaye akukho jamming.